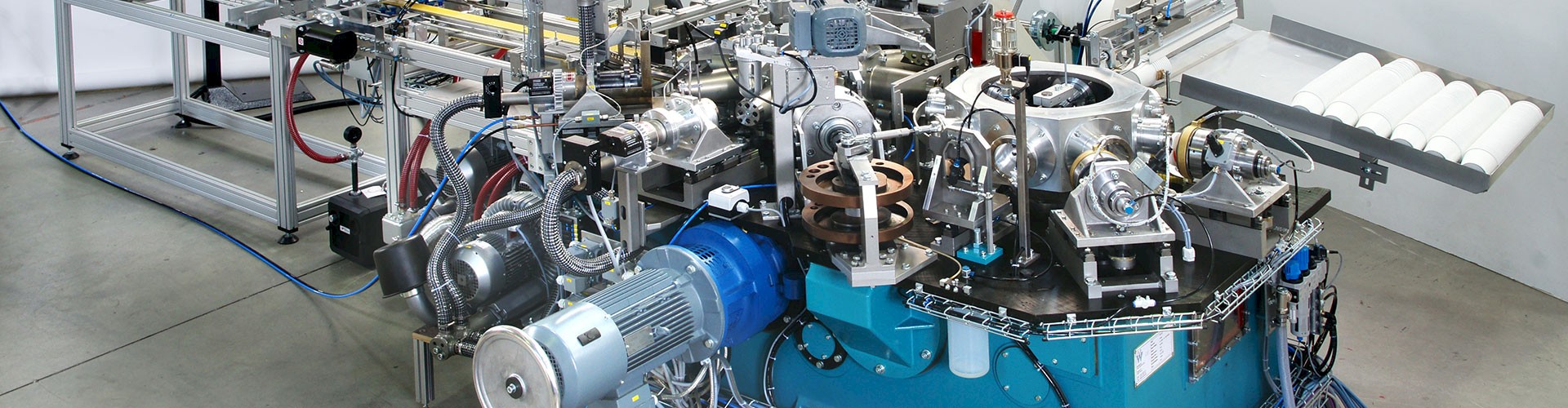

ST-1 / ST-2

Custom made single or twin turntable machine family

Special advantages of these machines:

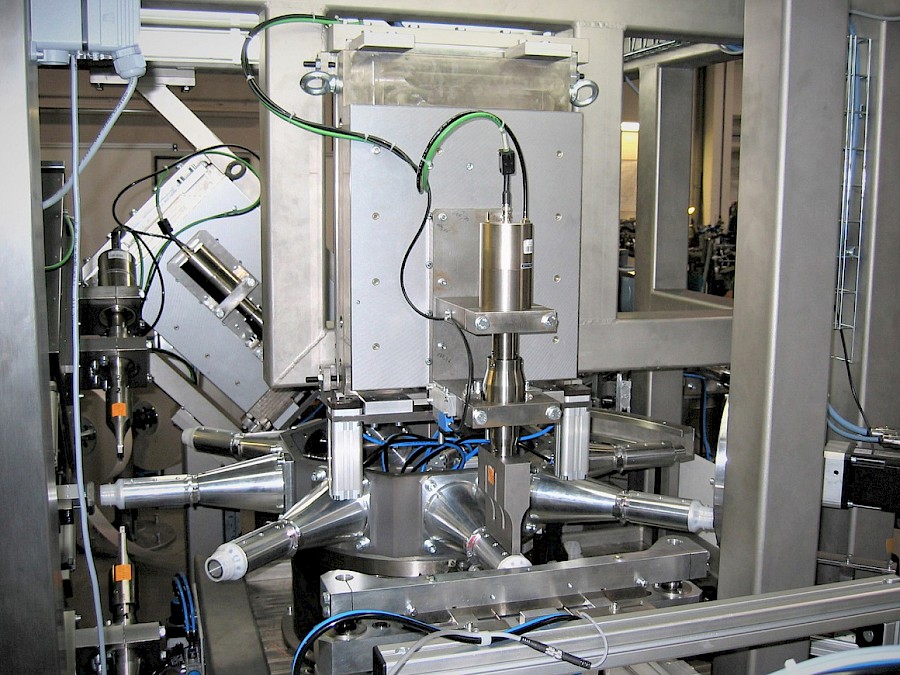

The trend-setting drive and control technology used ensures highly precise and adjustable positioning of all stations.

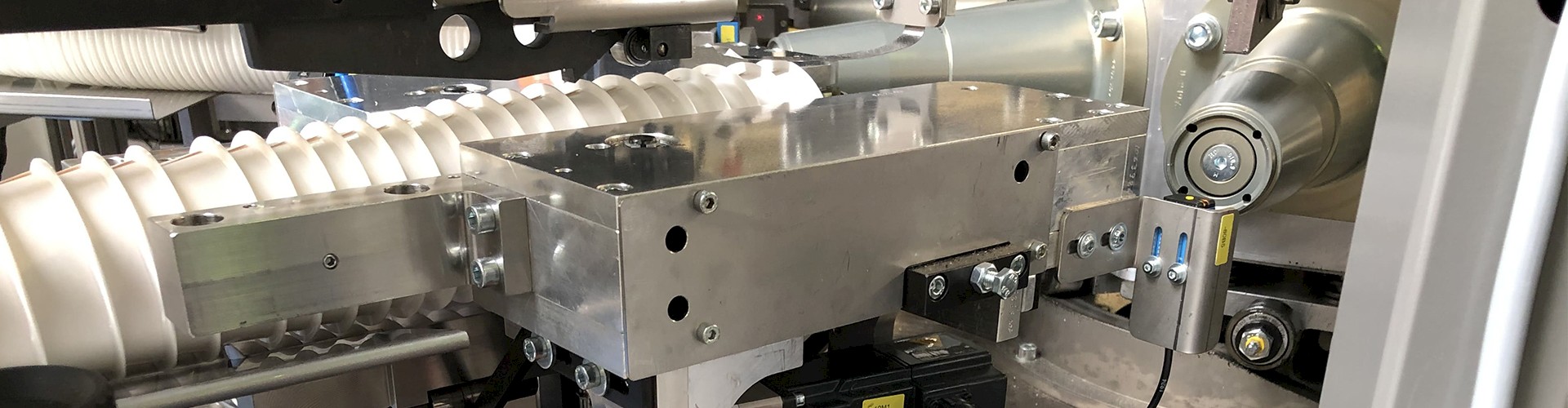

Integrated edge processing for preparing and sealing the inner edge using the "Skiving and Hemming" process. [Only for web-fed solutions]

Examples:

ST-1-90 - blank-fed single turntable machine for the production of gable top containers with a circular recessed base including standard screw on cap.

Screw caps are sealed using ultrasonic technology, base and side-seams using hot-air sealing technology.

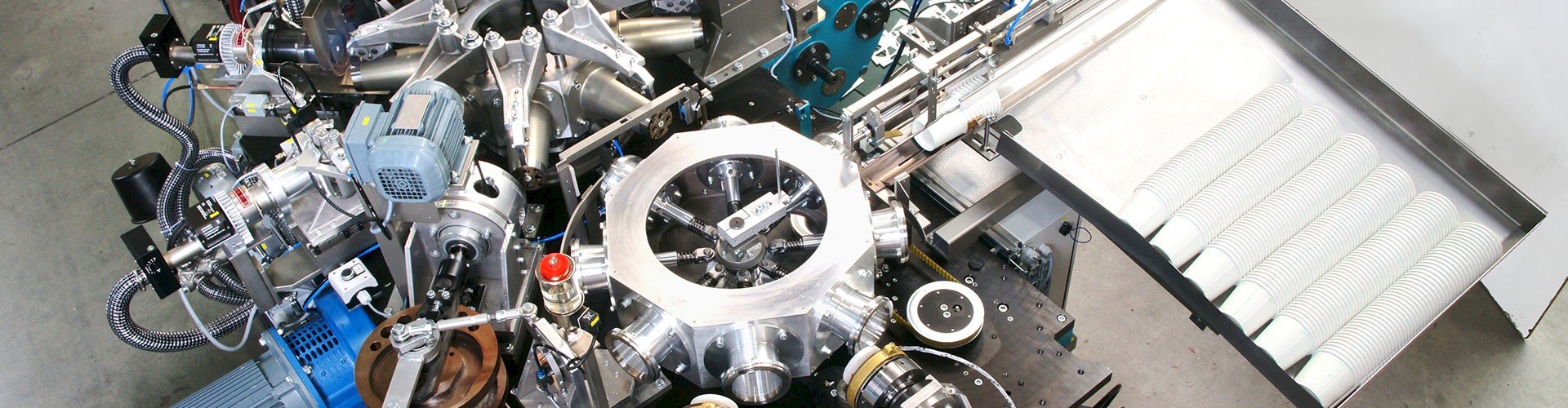

ST-2-85 - reel--fed twin turntable machine for the production of paper bottles with standard PE screw-on cap and PE laminate to suit the barrier requirements for the sidewall and base. The tops are sealed using ultrasonic technology, sidewall and base using hot-air.

These bottles can be produced in sizes (fill volumes) from 250ml (8.5oz), to 1000ml. (34oz)

Technical data:

On request